Recent Breakthroughs in 3D Bioprinting: A Look at Trends and Challenges

June 13, 2025 | Friday | Views | By Gunjan Bedi, Research Analyst, Roots Analysis

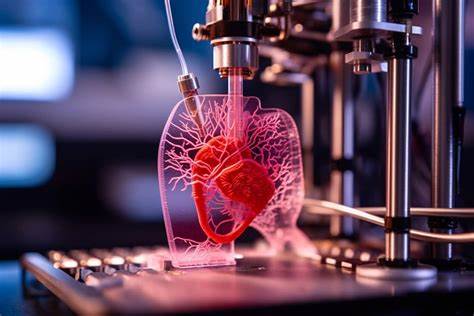

Opening avenues for healthcare industry to develop functional tissues and replace with damaged tissues

image credit- shutterstock

3D bioprinting technology bring a new revolutionary wave to healthcare industry. This technology combines biomaterials, bioinks and 3D printing to develop specific structure that mimics functional tissue or organ. Currently, these bio-printed models use as a drug screening and discovery tool to accelerate the production of potential drugs. However, researchers are continually focusing on the development of bioinks with improved mechanical properties, better printability, and biocompatibility to mimic the natural extracellular matrix of tissues.

The recent breakthrough includes the introduction of elastic hydrogel materials, cellular matrix and incorporation of functional cells and tissues, such as autologous mesenchymal stem cells for the reconstruction of bones. This elastic hydrogel material is specifically designed for 3D printing of soft living tissues like blood vessels. Additionally, cellulose-based inks are also gaining traction owing to their versatility in drug discovery, tissue engineering, bone reconstruction and regenerative medicine. As researchers progressively explore 3D bioprinting across various healthcare applications, the transformatory innovations in this field is clear and obvious in future.

3D Bioprinting: Current Landscape

3D bioprinting offer a precise control to print tissue structure that can act as a fully functional tissue for regenerative medicine, bond bandages to heal wounds, weight bearing bone reconstruction and skin grafts to address the specific challenges encountered during foot and ankle surgery. It is worth mentioning that weight bearing bone reconstruction is a new dimension of the 3D bioprinting to deal with weight-bearing defects within ankle and foot occurred due to the accidental injuries and tumour resection or charcot foot.

These foot and ankle defect can lead to instability, pain, and impaired mobility, thereby significantly impacting patients’ life. Although traditional bone grafting approach, such as allografts, autografts and bone substitutes are available, there are certain limitations, such as morbidity, donor site pain and variability rates of resorption may hinder the treatment.

3D Bioprinting fundamentally involves an approach of bioinks deposition in a spatial manner to create a 3D structure that works like bone tissue. Several bioprinting techniques, such as extrusion-based bioprinting, inkjet-based bioprinting and stereolithography-based bioprinting poses the ability to fabricate scaffold with controlled pore size and interconnectivity, which is essential for nutrient diffusion and vascularization. Therefore, the precise incorporation of multiple cell types and growth factors with scaffold, mimicking the biochemical environment of bone tissue holds an immenseopportunities for personalised bone reconstruction in the ankle and foot.

A report by Roots Analysis has pointed out that the 3D bioprinting market is expected to jump from $4 billion in 2024 to over $23 billion by 2035. That kind of growth, over 17% each year, is pretty telling. Clearly, this field isn’t just growing; it’s taking off in a big way.

Current Research for Weight Bearing Bone Reconstruction

Several preclinical studies are presently demonstrating the feasibility of bioprinting bone constructs with improved mechanical strength and osteogenic potential for load bearing applications. For instance, a recent study, scientists have successfully shown the development of biomimetic structural design in 3D-printed scaffolds for bone tissue engineering. Scientists have successfully optimized key parameters in biosensitive materials, such as tissue connectivity, porosity, pore size and mechanical strength.

This structure mimics the functional complexities and structural integrity of native bone, thereby enhancing the mechanical performance for weight bearing capabilities. Furthermore, the study further highlighted the integration of advanced technologies, such as CAD and AI, enable the designing of patient-specific scaffold design for weight bearing bone construction. In case of significant bone loss due to trauma and injuries, these bioprinted constructs can help to fill large bone defects to restore biomechanical function.

Recent Case Study of 3D Bioprinting and Bone Defect Correction

Bioprinting technology has given a new direction to the healthcare industry, allowing treatment of patients with significant bone defect due to accidental injuries. It is worth mentioning that a recent case study has been published in Journal of Orthopedic Case Reports highlighted the successful treatment of a 38-year old male patient with critical-size bone defect with 3D printed mesh implants.

Initial treatment was done by doctors with fibula plating and external fixator. However, the fracture still shows atrophic non-union and 2.5 cm limb shortening. Considering the requirement, a team of doctor operated with 3D printed titanium mesh implants with a plate constructs. After 1.5 year, a good bone integration and ambulation restoration has been noticed in patient’s CT scan.

Top Trends in 3D Bioprinting Technology to Keep a Watch

The field of 3D bioprinting technology is witnessing rapid advancements, exploring new possibilities in regenerative medicine, tissue engineering and pharmaceutical research. Some of the trends that are must to watch in 3D bioprinting technology are listed below.

- Stimuli-Responsive Biomaterials

Industrial players are making significant progress in creating novel biomaterials and bioinks. The focus will be on the development of stimuli-responsive biomaterials with improved biocompatibility, mechanical strength, printability, and ability to mimic tissue environment.

For instance, collagen, alginate, gelatin, and decellularized extracellular matrix are currently being refined to improve structural integrity and cellular interaction. Furthermore, cellulose-based bioinks, composite bioinks and synthetic polymers, such as tailored hydrogels are currently being developed to offer precise control, bioactivity, reduce degradation properties and load bearing applications.

Additionally, the researchers are focusing on ceramic based materials, such as hydroxyapatite and tricalcium phosphate which are primary components of bones. They exhibit excellent osteoconductivity and can enhance bone formation.

- 4D Bioprinting Technology

4D bioprinting technology has recently caught attention as it helps to create tissue structure made with stimuli-responsive materials. The tissue structures created with 4D bioprinting and stimuli-responsive materials has the ability to change their function and shape over time in response to external stimuli, such as light, pH and temperature. This technology can be utilized to design vascularized bone structures that helps in establishing a bionic microenvironment, enhancing stem cell differentiation in the post-printing phase.

- Multi-Material Printing

One of the significant trends to experience in 3D bioprinting technology is the rapid incorporation of multi-material printing capabilities. Notably, the integration of multi-material printing with 3D bioprinting simultaneously allows the creation of heterogeneous tissues with biomaterials and different cell types in precise spatial arrangements. This spatial arrangement of biomaterials can mimick the complexity of natural tissues with higher precision.

Furthermore, the ongoing innovation in multi-material printing increases the speed of bioprinting, which is essential for constructing larger tissue.

- Nanotechnology and Microfluidics

Nanotechnology is gaining traction in 3D bioprinting field to enhance the biological and mechanical properties. Additionally, industrial players are focusing on combining bioprinted tissues with microfluidics systems to promote self-assembly of microvascular networks and provide nutrient and waste exchange. The integration of these technologies helps to make patient-specific tissues and weight bear bone structures by using patient’s own cells, thereby reducing the risk of immune rejection.

Furthermore, the introduction of nanotechnology, microfluidic and smart biomaterials can solve numerous issues, such as corrosion resilience and bacterial adhesion associate with non-metallic implants that are used for structural support in ankle and foot surgeries.

- Integration of Artificial Intelligence

Artificial intelligence is currently being integrated with 3D bioprinting technology to design structure of complex tissues and predict cell behavior. Moreover, the integration of artificial intelligence algorithm with 3D bioprinting technology helps to analyze tissue properties and cell behavior, which further helps to optimal biomaterial compositions and printing conditions. Furthermore, AI integration ensures faster printing speed, enabling manufacturers to develop organs and tissues for regenerative medicine applications.

Challenges in 3D Bioprinting Technology

3D bioprinting emerged as a remarkable tool for wide range of applications in healthcare industry. From cellular based research to developing 3D printed tissues and disease models for regenerative medicine and drug testing, 3D bioprinting is offering a new direction to repair damaged tissues while minimizing the requirement of organ transplant. Despite immense progress, there are several challenges that hinder its progress.

Post-Printing Editing

In 3D bioprinting, the physical forces exerted on the cells during printing specifically during extrusion-based printing approach can damage the cell membrane, resulting into irregular share and reduce functionality. Furthermore, it is difficult to maintain a suitable environment and physiochemical properties during post-printing editing. Hence, supporting and controlling post-printing editing in-vitro is a significant challenge for the industrial players.

Post-Printing Editing Solution

In order to overcome the editing challenges, Falandt et al. have developed a light-based volumetric printing technology. This technology can photograft thiolated compounds on hydrogel post-printing, with custom geometric share and accurate spatial arrangements, enabling high-resolution printing with high speed. This new approach is unlocking the possibilities to develop biofabricated scaffolds that can mimic the biochemical environment of organ and tissues.

Vascularisation Challenges

One of the significant bottlenecks in 3D bioprinting is establishment of functional vascularization to deliver nutrients and remove waste. Notably, the development of perfusable microvascular networks within bioprinted constructs is a complex engineering task and replicating complex microarchitectures along with heterogeneous cell populations with currently available 3D bioprinting technology is a significant challenge.

Scalability Issues

Printing large scale tissues and organs with traditionally available 3D bioprinting technology is a major challenge. With conventional 3D bioprinting technology it can be tricky to maintain structural integrity and cell viability over longer printing times and large volumes. Additionally, lack of standard protocols for bioprinted constructs may impede the adoption of 3D bioprinting.

Conclusion

3D bioprinting technology have opened avenues for healthcare industry to develop functional tissues and replace with damaged tissues. Despite exponential growth, the industrial players need to address these challenges to overcome the limitations. However, technological innovations will remain a cornerstone for 3D bioprinting technology market and future consideration will also emphasise reducing printing cost and enhance sustainability for widespread adoption.

Gunjan Bedi, Research Analyst, Roots Analysis